|

|

Post by Troll on Feb 5, 2010 20:30:06 GMT -5

Is there any write ups on how to port and polish a head anywhere or where would be a good place to take one to have it done. I'm asking because it's something else I've thought about adding to my list of to do's on my scoot. I do own a Dremal just not to sure what bits to use, also think I have head somewhere I could practice on.

Also what kind of improvements am I looking at if I do port and polish the heads?

|

|

|

|

Post by meitianman on Feb 5, 2010 22:54:54 GMT -5

your gonna let the engine breath better by porting and polishing. you want the intake and exhaust ports to be the same size as the intake manifold and exhaust manifold to allow the maximum amount of air into/out of the engine. by polishing you are reducing the friction of the air entering and exiting the engine which if memory serves helps more with response times more then anything.

as for which bit to use im not entirely sure, i generally use those little stone bits but im pretty sure you can get a metal bit for removing material. make sure the head is fully clean of shavings before reinstalling, you suck any of that grit into the engine it could be ugly.

|

|

|

|

Post by Troll on Feb 5, 2010 23:23:50 GMT -5

Thanks Meitianman I'll have to give it a shot.

|

|

|

|

Post by cruiser66 on Feb 5, 2010 23:41:54 GMT -5

|

|

|

|

Post by rapidjim on Feb 6, 2010 9:48:04 GMT -5

Very interesting reading thank you for the link.

Jim

|

|

|

|

Post by felliott on Feb 6, 2010 13:06:24 GMT -5

Food for thought, the exhaust should flow 60% of what the intake does. Of course that means you have a flow bench to check it with, and most people do not. Just making the ports the same size does not always mean you have the flow ratio. The intake port works mostly on the low pressure principle and flow travels at about 1100 feet per second. The exhaust is mostly push out by the rising piston and travels at about 1700 feet per second on gas.

|

|

|

|

Post by Troll on Feb 6, 2010 19:20:04 GMT -5

After reading that link, I think I'll just go with an 80cc head or a performance one along with a cam. Then I'll start on the crank, I would hate to do all that work and no improvement. Thanks ya'll.

|

|

|

|

Post by cruiser66 on Feb 6, 2010 22:43:59 GMT -5

Your welcome, Jim and Troll. This might be fun to do if you had a spare head and didn't mind doing some extra wrenching.

66

|

|

|

|

Post by kliff on Feb 9, 2010 12:46:08 GMT -5

You too Troll, figured by now, you'd know the Scooter rebels site is the place for head work...

|

|

|

|

Post by JR on Feb 10, 2010 19:18:06 GMT -5

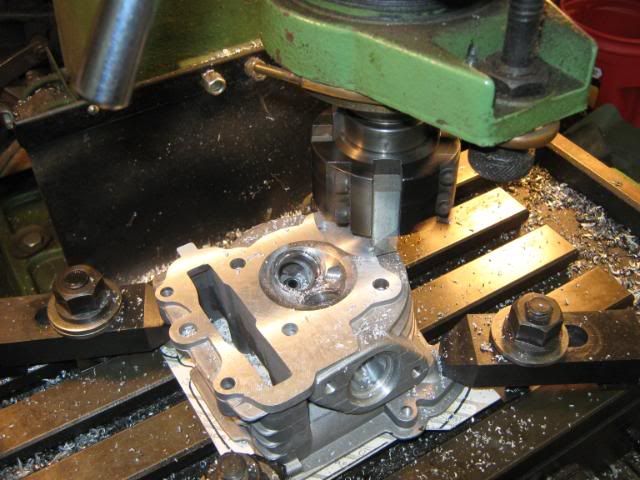

Is there any write ups on how to port and polish a head anywhere or where would be a good place to take one to have it done. I'm asking because it's something else I've thought about adding to my list of to do's on my scoot. I do own a Dremal just not to sure what bits to use, also think I have head somewhere I could practice on. Also what kind of improvements am I looking at if I do port and polish the heads? Troll got the dremel tool OK then here's just a few of the stones and such you might need;  You can get lots of different types from coarse to medium to fine stones and sanding disks to buffers for the final polishing! Now here's a picture of the intake manifold on one of my 250's before I sized it and polished it;  Very Very rough and even one of the vacuum port nipples was sticking out in the manifold almost a 1/4"!!  Also as you can see it was too small and the desired ID was 30mm so to work I went and just as this portion of 66's link said you need to do exercise patience and this is the final results!  Now granted a head is not as easy but still the same principal, not rocket science, just the right tools, patience and getting it done, plenty of good folks over here to help ya throught it! Good Luck JRR |

|

|

|

Post by kliff on Feb 12, 2010 7:46:42 GMT -5

LOL..... there ya go Troll. Them's the basics anyway, Dremel, handful of bits, grind away, and be happy. There are a few "details" missing though. Not all stones are equal. For years I used stnes only on ferrous metals, cast iron heads and blocks, and carbide burrs on aluminum or any non-ferrous material. But times change, and we need to progress with the times. I recently tried some Silicon Carbide burrs(advertised for non-ferrous use), and have been so pleased, I sent in an order for about 150.00 worth of the little buggers in about 8 differring shapes and sizes. They will be a good addition as second step process. Rotary file (alu cut profile) SiC stones polishing media... the blue rubber polishers dowsed in oil and kept moist are great! The actual porting, rough areas in the bowl area, are your enemy, I will telll you that. Shapes, sizes, radius's, and surface finishes.... sorry man, experience dictates I keep some knowledge to myself. Pay for some of my work, dissect it if you want, learn what you can, but at least I'll have been paid for that last tid bit of experience. I will say this though, even a 'JR" style job can be beneficial, the more time and effort you put in, the better your results will be. Be sure also, when porting to re-cut your valve seats when finished. You may have put a microscopic cut in either seat, close working proximity, UNKNOWINGLY! It will lead to a burned valve. If you don't re-seat, use a jewler's loupr for a microscopic seat inspection...the naked eye is NOT enough.  and don't forget the valves. That letterring on the head....gotta go, swirl polish, tulip area of the valve, swirl polish... it all works together Troll...   Anyone can do it... |

|

|

|

Post by JR on Feb 12, 2010 8:18:07 GMT -5

Yep carbide bits no problem have two sets myself 1/8" and 1/4" shank for larger die grinder but for sure one can get excessive and make a mess out of a head real easy as they require a steady hand and lot's of patience but the one thing that is for sure on the home DIY on these heads is this and hey I was just like anybody else after reading this I changed my mind; www.motorcycleproject.com/motorcycle/text/cows-porting.htmlNo matter how well one does a porting job unless you have a way to check it to see if the flow is correct then at best at home it's just an educated guess as to if you have helped it or not? I'm sure that the average fellow at home is not equipped with the kind of equipment necessary to properly test a head to see if it's at it's maximum performance level. Re-seating the valves yep even bought a brand new head and was shocked to see that the exhaust valve was not seated properly and would blow by but lapping the valves is again a simple process that the DIY at home guy can do with a simple hand lapping tool and the lapping compound and taking ones time and doing it right! It's safe to say that over 90% of the everyday folks out there don't have machine shop equipment to do the more elaborate work that can be performed with this kind of equipment. But it doesn't mean that you cant get good results at home either especially for the everyday running down the street scooter. The other thing that was a surprise to me was the mention of the "eye candy" polishing and that it could actually be harmful and needed to be limited to a rougher texture type polishing! I like a lot of folks thought the smoother the better and it lots of aerodynamic things I've worked with it is the rules but in this case the air is also mixed with the fuel so the equation is changed! But it's just common sense like I said before without the testing equipment home porting and polishing is at the best good guessing. Amazing what one can learn by reading other things from folks who work on this stuff! LOL JRR |

|

|

|

Post by diablo on Feb 24, 2010 20:49:27 GMT -5

Is there any write ups on how to port and polish a head anywhere or where would be a good place to take one to have it done. I'm asking because it's something else I've thought about adding to my list of to do's on my scoot. I do own a Dremal just not to sure what bits to use, also think I have head somewhere I could practice on. Also what kind of improvements am I looking at if I do port and polish the heads? two stroke tuning for performance is a great book that will help explain everything |

|

|

|

Post by kliff on Feb 26, 2010 17:28:51 GMT -5

JRR's referance to a fllow bench for maximizing flow and performmance is right on the money. I wish I still had mine, but after watching it sit dormant for severral years, I sold it. So all I can go by are experiences of what worked best when, memory, guesstimating, and past experience are my guides now. BBut then again, I'm not working on the MEGA-HP-BUCK engines nno mo, neither. I'm just enjoying a hobby, and a fast dissappearing art, as CNC is replacing even us old dinosaur porters. Just out of curiousity though, I decided to keep track of all the tools I use in association with a port/polish/surface job. So here we go..... gotta have bits, burrs, polishers, and spares. The first pics, are what I used on this head:   some "back-up" spares.... and more...   Gotta take it apart & re-assemble  That'll get you started with porting, and polishing, now for surfacing, either to true up a bad surface, or a heavier cut for compression, we move on...   Set-up time alone for surfacing, can take an hour, sharpenning 4 individual cutters in one head, another hour, "truing" them all to the same depth, another hour....  Did I forget about polishing, and lightenning the valves?  I like my little old Crafstman/Atlas for this task   Don't forget to re-CUT your valve seats, before hand lapping the valves.   That's a pretty standard job. Start making fire rings for the exhaust port, welding up ports to change dimensions, re-angling ports..... it brings into play many more tools. But sometimes an over-simplification of porting, can lead too many folks down a thorny path, to where they think they can, they own "that many stones," next thing you know, a head is ruined. Granted, mine are NOT NASA approved, but I doubt anyone will notice anything detrimental to performance. And those that can, as I have in the past, with much lesser equipment than this attain positive results.....well guys, all I can say is it IS ADDICTIVE. Good luck, and have fun, but when learning, ALWAYS have a good spare head in reserve, otherwise, Murphy's Law will bite you dead square in the arse! |

|