|

|

Post by usfmarine on Mar 23, 2009 1:55:59 GMT -5

I just received the mandrel tubing for my custom exhaust. Before I hand over the tubing over to the welder, I wanted to know if anyone had some extra bits of advice. Columbia River Mandrel Bending www.mandrel-bends.comDescription Part # Price 1 x 1.50" OD, 16 Gauge, Mild Steel Straight Tube MS-150-065 $3.75 1 x 1.25" OD x 1.80" Radius Mild Steel Pro Builder Kit PBK-125-180-MS $34.99 1 x 1.25" to 1.50" Transition Cone - Material: Mild Steel TRA-125-150 $12.99 3 x 1.25" OD, 16 Gauge, Mild Steel Straight Tube MS-125-065 $10.50 Federal Express (1 x 9.46lbs) (Home Delivery (3 days)): $13.92 Sub-Total: $62.23 Total: $76.15   Shipping was fast and I received terrific pre-sales support over the phone from these guys. Parts appear to be as advertised. Oh ya, I chose the sharpest 90 degree and 45 degree bends they offered. I believe it may have been a bend radius of 1.8" The flange was fabricated and is being shipped to me from tp555. That will be arriving in the mail in the next few days. Thanks tp555! My plan is to use the 90 degree bend right out of the flange. From there, 1.25" tubing to just under the fan/dipstick. From there, use the second 90 angle to standard muffler position. At that point, using the 1.25" --> 1.50" coupler. I am transitioning to 1.5" because all of the common and cheap reasonators are 1.5" or larger. I'll only use the 45 degree angle joints if I need to maneuver some more. All of the bends are 1.25" outer diameter, so a little under 1.25" for ID for this 16 gauge steel. Based on what i've read here, this size diameter will be just a tad larger than ideal for my 150cc scoot. Definitely a free-flow setup. Besides having a specific plan to give to the welder, are there any other things I should discuss with him? I don't know anything about welding. How about the tubing's position with the flange? Should the tubing fit through the flange and then flush on the opposite side? Thanks guys, I will use this thread to show my progess after the welding is done. In other news, here are a few photos of some scooters I saw this last weekend while in Vegas. I was going to the Hooters casino for lunch and walked past the parking lot at the Tropicana resort to find 50 or so vintage scooters.      I can certainly appreciate these restored scooters, even if they are overpriced and overhyped.  |

|

|

|

Post by phaze on Mar 23, 2009 5:41:17 GMT -5

i like the bug myself lol, are you cutting to fit? that'll be a pretty expensive pipe. when done wont it

|

|

|

|

Post by performancescoot on Mar 23, 2009 9:35:44 GMT -5

Wow, Hooters has a casino now? I reallly got to get up there.

Interesting project, I don't have any advise, but why did you choose to go with such a large diameter? The exhaust valve is only 3/4 of an inch and with a header, "velocity" rather than just shear size helps create a slight vacuum to help fully evacuate the cylinder. I'm just kind of wondering why you went so big.

|

|

|

|

Post by usfmarine on Mar 23, 2009 10:19:54 GMT -5

phaze5: Tubing was $76 shipped. The welder said it will be $50-$100 for his time to cut it and weld it together. Is that reasonable? performancescoot: The Hooters Casino is not nearly as cool as it sounds. It is off of the strip, and it feels like it is off the strip too. The Hooters restaurant inside the Casino is not nearly as good as my local hooters. It is more expensive and the girls were sub-par at best. Anyways, I heard that just over 1" would be ideal for 150cc, and I am going to be about 10% larger than the ideal inside diameter. So, not a big deal. I had wanted to go 2" originally  It leaves me a little room for upgrades in the future. My current pipe that came stock is kinked in several places. I can't imagine my stock exhaust being anything more than .75" in the corners, not a good flow. I'm going from about .75" to 1.12', I hope to see some decent performance gains with this. |

|

|

|

Post by xs650 on Mar 23, 2009 10:43:41 GMT -5

phaze5: Tubing was $76 shipped. The welder said it will be $50-$100 for his time to cut it and weld it together. Is that reasonable? That's a good price if he does good job of fitting it and makes it look good. Cutting and fitting is fairly time consuming, a lot more so than bending one in a tube bender. Too bad there aren't more mandrel benders in shops. Take your plans and scoot over to him and spend some time talking them over with him to be sure you are communicating clearly. Show him a few things that matter to you. For instance, maybe how close the pipe should be to things, if it should run parallel to the frame, etc. Ask for his advice, he'll probably give it anyway.  Don't give him too many restraints or it will add time and piss him off. |

|

|

|

Post by usfmarine on Mar 23, 2009 11:03:11 GMT -5

Thanks XS, that's good advice.

How would I know if he did a good job welding it together?

|

|

|

|

Post by xs650 on Mar 23, 2009 11:15:34 GMT -5

Thanks XS, that's good advice. How would I know if he did a good job welding it together? If he's a pro in a shop that does high end exhaust systems, it will be good enough. As long as it doesn't leak and isn't too ugly, it will be good. Making the pipe gas tight requires far more weld than is required for strength, Appearance will be the biggest variable. Are you going to leave the welds as is, have him grind them down, or grind them down yourself? If he knows they are going to be ground he might weld a bit differently, so talk that over with him before hand. If you want the welds ground off smooth, it's best to pay him for the work. He will have the tools to do it quickly and if he does go through a weld, then it's still his problem. It's dirty, nasty, time consuming work at home. RE your earlier question. The tube should go most of the way through the flange but not stick up at all on the gasket side of the flange.. It's ideal if it's flush with the gasket surface. That 16 gauge feels lot better than car parts store exhaust pipe, doesn't it? |

|

|

|

Post by sc150rider on Mar 23, 2009 11:26:07 GMT -5

You got great timing usf:

I was up this morning at 3am making me a template for my exhaust flange.

Had the CVT cover off and figured now would be a good time to do the exhaust as well...It also helps that I've only got till Tomorrow (the 24th), and I'll lose my indoor parking.

But anyways...found out that even with a 1" OD pipe would be bigger than the exhaust port on the engine. So, I'm gonna start with just the 1". If I can get where I want, I'll have to figure out how to post pictures, since I got a new cellphone now that has a camera on it.

How long is that transition cone?

|

|

|

|

Post by usfmarine on Mar 23, 2009 12:24:59 GMT -5

XS650: Yes, the 16 gauge steel feels very substantial. I can't imagine it succumbing to cracking/bending. Of course, the strength of the welds will be the most important part. Grinding down welds? I've never heard of that, but by the context it sounds like the welding process may leave excess steel pooled up around the welds, and I guess for aesthetic purposes people want that grinded down to make it smooth (I imagine that it would look like the bubbling a hot glue gun makes). I will certainly bring that up that topic with him. I don't need to draw up detailed instructions do I? First of all I don't know how to do that, especially when it comes to tubing plans that involve 3 dimensions... I'm going to tell him to mirror the stock exhaust as much as possible. sc150rider: The transition cone is about 4 inches long, I can measure it when I get home. Are you using mandrel bends with your 1" OD pipe? I look forward to comparing performance gains with you over stock. I bet your 1" pipe will give you a little better performance boost at the 150cc range than mine. However, if I am not seeing a big improvement after putting on a Mikuni 28mm flatslide, a free-flow air filter, and this new custom exhaust, I am gonna be upset  |

|

|

|

Post by sc150rider on Mar 23, 2009 12:36:45 GMT -5

Knowing that the cone is about 4 inches is close enough for me...that's gonna be the length of my 1st exhaust attempt. If I can't get it to do what I want I'll have to try again using a full length exhaust like you're doing.

I'm also trying to NOT get a bigger carb...we'll see........

|

|

|

|

Post by d on Mar 23, 2009 12:43:37 GMT -5

|

|

|

|

Post by xs650 on Mar 23, 2009 12:53:59 GMT -5

XS650: course, the strength of the welds will be the most important part. Even 1/2 arsed gas tight welds will be more than strong enough. That's not an issue. Depends on the welding process and how good the welder is. A nice weld can be attractive and not stick up much if at all. See what the welder recommends. It's best if you can skip grinding the welds smooth. No, was under the impression from an earlier post that you were going to. Telling him how you want it relative to your stock exhaust is a good way to do it. |

|

|

|

Post by fastasssr20 on Mar 23, 2009 16:25:33 GMT -5

If they tig weld it you probably wont want to or need to grind it as long as the welder is decent. If it is mig welded you might want/need to grind it down if it is ugly. The weld of course will be stronger if you do not grind it. If you can have it tig welded go that route imo it will look much nicer

|

|

|

|

Post by usfmarine on Mar 23, 2009 21:59:42 GMT -5

Got my flanges from tp555 in today's mail. They look nice. One is 1 1/8" diameter, the other is 1 1/4" diameter. Both are 1/4" thick. Could not be happier. Thanks tp555, you helped me big time! Gonna take my scooter to the welder tomorrow, I imagine he'll have it done pretty quickly. As far as driving this bad boy home the 3-5 miles from the welder. Currently, I have a 105 main jet, and a 35 pilot in my stock 24mm carb. I don't have a truck to get it home, so should I just pop in my 110, or 115 main jet and hope for the best? This is while temporarily keeping the airbox. I really don't want to buy more jets for the stock carb considering it is going to be replaced with a Mikuni 28mm flatslide. Any advice? Thanks guys! |

|

|

|

Post by odie2ooo on Mar 23, 2009 22:32:19 GMT -5

If it were me then I would pop in the 115. IMO its always better to run a little rich than it is to run lean. How does your sparkplug look now with the 35,105 jets in it?

|

|

|

|

Post by usfmarine on Mar 23, 2009 22:36:47 GMT -5

greyish  Haven't checked in a while actually. I ordered a #115 main jet from a place on ebay 3+ weeks ago, still hasn't arrived. I'm about to post negative feedback for "exportstrength" the ebay seller. His store is called Scooter Assassins. Buyer beware, it will take a month to get your stuff from this seller. |

|

|

|

Post by odie2ooo on Mar 23, 2009 23:03:22 GMT -5

Greyish is not to bad. I like my plug to have sort of a creamy brownish color. I think you would be to lean if you leave the 105 in there with the custom exhaust. If you have a bigger jet then I would put it in. It may not hurt the scoot to leave the stock jets in with the custom exhaust for the short ride home but if it was my scoot I know I wouldn't be that lucky.lol

|

|

|

|

Post by usfmarine on Mar 24, 2009 0:19:20 GMT -5

Took a few more pics of possible exhaust designs. Of course, I have not trimmed the pieces to fit, but these are some overall shapes.   Option #1: two 90 degree turns - maybe worse flow, but perhaps some added back-pressure.  Option #2: one 90 degree turn, and two 45 degree turn. I'd imagine better flow with a little less back-pressure.  Is either one preferable to the other, or are the differences negligible? |

|

|

|

Post by phaze on Mar 24, 2009 5:36:42 GMT -5

how much for your muffler? welders arent cheap, but he seems fair ? i say he charges a 100 seeing that is his range lol.

if you get a nice bead dont grind it off thats the mark of how good he welds, personally i'd be pissed unless you were chroming? is yours gonna look like a works pipe?

i had a 107 i put a 115 in it and it should get you home imo.

|

|

|

|

Post by usfmarine on Mar 24, 2009 9:06:11 GMT -5

The reasonator that i'm having put on there is like $25-$35. Labor is in the $50-$100 zone according to him. This is kind of a friend of a friend hook-up too. I'd imagine doing this would be more expensive for someone else.

Will post photos of the completed exhaust in a few days.

|

|

|

|

Post by phaze on Mar 24, 2009 14:23:06 GMT -5

you didnt say you got the hook up that changes everything then.

|

|

|

|

Post by JR on Mar 24, 2009 14:58:18 GMT -5

USFMarine Here is a couple of pictures of good welding for a reference. These are welds done by myself on Stainless Steel with a tig welder which can be used on you pipe too. Most good welders will use a "Mig" wire welder on muffler pipe and yes 16ga is standard for muffler pipe but it sometimes over a period of time can stress crack but heck the scooter will probably be wore out before that happens.  Another welding picture. Also you may want to consider painting your exhaust with some high temp grill paint as this pipe is going to rust after it gets hot and then gets some moisture, I like the charcoal black. Just got back from camping and saw all of your exhaust stuff and it's going to look good. Take it from me a certified welder if he's good you won't have to smooth or grind. Good welders pride themself on good looking welds.  Another picture one weld has not been polished yet with a brush that's whay it's still blue looking. JR |

|

|

|

Post by usfmarine on Mar 24, 2009 16:59:40 GMT -5

Thanks for the pics jrryan, I'll use those as a reference.

|

|

|

|

Post by odie2ooo on Mar 24, 2009 18:03:03 GMT -5

I like the header design with the 1 90 and the 2 45's but it really depends on the type of muffler you get. How free flowing is the muffler? I would use the 2nd design as long as the muffler itself you pick has a little resistance for back pressure. Looking good keep up the good work

|

|

|

|

Post by usfmarine on Mar 25, 2009 10:50:05 GMT -5

Odie, there really won't be a muffler. Just a glasspack resonator or some type of flashy dual exhaust I believe. Knowing that, would you advise me to go with the 2 90 degree angle design?

I'd imagine 2 90 degree angles may give a little bit more back-pressure as opposed to the 2 45 degree angle option in the above photos.

What do you guys think?

|

|

|

|

Post by odie2ooo on Mar 25, 2009 15:59:04 GMT -5

In my experience most if not all engines perform best with a little back pressure. If it was me doing it I would used the header design with the 2 90's to provide a little back pressure BUT i am not an expert. This is just my 2 cents.

|

|

|

|

Post by kliff on Mar 31, 2009 18:43:33 GMT -5

Any updates? Pics?

|

|

|

|

Post by usfmarine on Mar 31, 2009 22:37:12 GMT -5

Kliff, yes, I went to the "Muffler Man" today for a status check. WOW, it looks awesome! Way above expectations! I took a bunch of video and photos, however, for some reason all these files were corrupted on my SD card. All of the other photos that were on my SD card are still there, but every photo/video I took today is gone! I have no idea what happened.

The scooter is louder than a V-twin, I swear to God. It sounds deep and powerful, all that from a 150cc. A straight 1.5" pipe doesn't hurt! The project is 80% done. He just has to trim the pipe. When I was revving it, a bunch of the other mechanics from other shops walked up and started asking me about the scooter. I am running a memory card recovery program now on my SD card, hopefully I can get some of these photos back. Unfortunately, I think the videos will be corrupted and too fragmented.

You're going to flip when you see the exhaust, it looks cleaner than anything i've seen on the internet.

|

|

|

|

Post by odie2ooo on Mar 31, 2009 23:03:37 GMT -5

Its always great when projects come out better than expected. Glad to hear everything is going good

|

|

|

|

Post by usfmarine on Mar 31, 2009 23:04:18 GMT -5

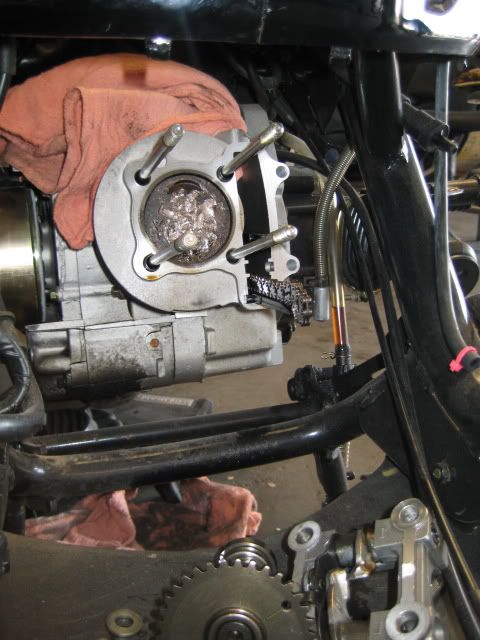

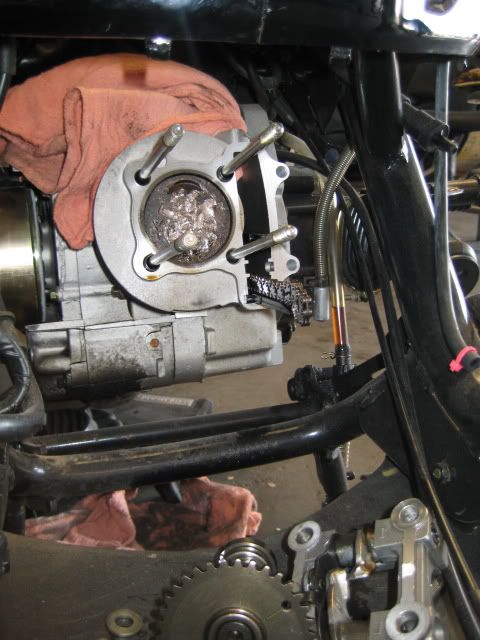

Ok, got some photos, but no video of the MEAN-sounding exhaust! Please note, the pipe is going to be trimmed by ~3 inches, and a chrome tip will be added. The "Muffler Man" was awesome (his name is Roger). He painted the exhaust black (he said he actually heated it up and applied some weird stuff to it so that it soaked into the metal or something, he did 2 coats). The welds are perfect, it looks so professional. He even fab'd up a gasket from scratch because I failed to give him one. I was blown away when I first saw it! The Muffler Man even removed some chrome from my stock exhaust and installed it over the bent portion of the exhaust so that I never burnt my leg or foot. He did that on his own. Anyways, I have to put a plug in here for Roger: Muffler Man 2954 San Luis Rey Rd Oceanside, CA 92058 (760) 967-3855    Ok, so I said the other mechanics were coming out of their holes and asking about my loud@ss scooter. Well this one mechanic said he had a scooter and it was having problems. He asked me to look at it (ya, a mechanic asked me to look at his scooter, ha ha). Well, here is what I saw.   The piston is gouged to hell! The exhaust valve is bent in half and has fallen out and the head looks like someone took a jackhammer to it for a halfday. I don't even know what happened to it. The guy said "I can't find anyone who carries parts for it." I said, "I can give you 10 sellers for those parts." The mechanic couldn't believe it. I told him I'd return with a list of websites, names, and auction numbers for a new head/piston/cylinder. It feels good to be able to help someone with this stuff. Btw, i've never seen the brand of his scooter, definitely something fresh off the boat from the sweatshops of China. It was a 1P57QMJ. I told him to make sure he bought parts for the "P" version of the 157QMJ. I probably should have started a new thread about me trying to point this guy in the right direction. Anyways... |

|

Don't give him too many restraints or it will add time and piss him off.

Don't give him too many restraints or it will add time and piss him off.

Haven't checked in a while actually. I ordered a #115 main jet from a place on ebay 3+ weeks ago, still hasn't arrived. I'm about to post negative feedback for "exportstrength" the ebay seller. His store is called Scooter Assassins. Buyer beware, it will take a month to get your stuff from this seller.

Haven't checked in a while actually. I ordered a #115 main jet from a place on ebay 3+ weeks ago, still hasn't arrived. I'm about to post negative feedback for "exportstrength" the ebay seller. His store is called Scooter Assassins. Buyer beware, it will take a month to get your stuff from this seller.