Post by usfmarine on Mar 15, 2009 4:13:54 GMT -5

I have read so many good write-ups here on scoot dawg, I thought I should try to produce my own to help some dawg in the future with this task. This is written for the novice out there who is jumping in head first.

The problem: At wide-open-throttle there is very little vacuum pressure, therefore a vacuum operated fuel pump frequently cannot produce enough fuel to keep up with engine demand. When riding at WOT for distances greater than 5 or so miles, I sometimes would have a bog from "fuel starvation." It is my understanding most if not all Chinese 150cc scoots come with such a vacuum operated fuel pump. Of course, a fuel pump is only necessary when your fuel tank is below the level of the carburetor. So my carb was not getting enough fuel to keep up with the engine, what are my options?

Two Solutions

Solution #1: Replace the stock vacuum pump that looks like a hockey puck with a higher volume vacuum-operated pump. A very popular replacement is the Mikuni DF-44 vacuum pulse pump. I have read many accounts that using this Mikuni DF-44 fixed the dawg's fuel starvation issues.

This is what my stock vacuum-operated fuel pump looks like.

This is what the Mikuni DF-44 looks like:

The Mikuni DF-44 can be rebuilt too at minimal cost. Here is one reliable dealer who sells this popular DF-44. www.aircraftspruce.com/catalog/eppages/mikunifuelpump1.php

Solution #2: Install an electric fuel pump. By going with an electric fuel pump, you will no longer rely on vacuum hoses in order to suck fuel into the carb. I've read that electric fuel pumps are rated to last much longer than the diaphragms in the vacuum-operated fuel pumps. Also, if you plan on installing a larger carburetor and performance parts on your scooter, you will likely need to send fuel to the engine at faster rates. This is the reason I went with the electric fuel pump as opposed to the Mikuni DF-44.

So which electric fuel pump? Well there are many choices, but there are a couple of frontrunners.

This a link to the Mr. Gasket 42s. However, the one I bought from Autozone was bulkier and made out of black plastic, with a black plastic mount.

www.amazon.com/gp/product/B000BWE4RC?ie=UTF8&redirect=true

It is a 2-3.5 psi electric fuel pump. Many dawgs have installed this electric fuel pump with success. It is available at Autozone, and many online dealers. I chose not to go with the Mr. Gasket 42s because it was slightly larger and more awkward than the Facet fuel pump I went with.

The electric fuel pump that I went with is a Facet cube fuel pump.

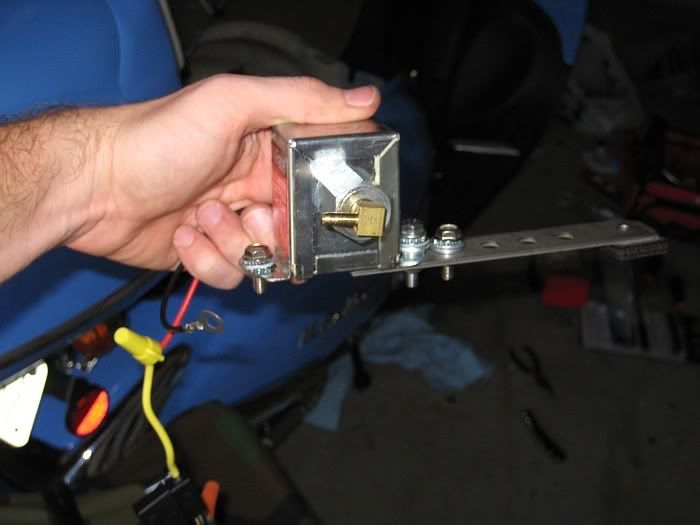

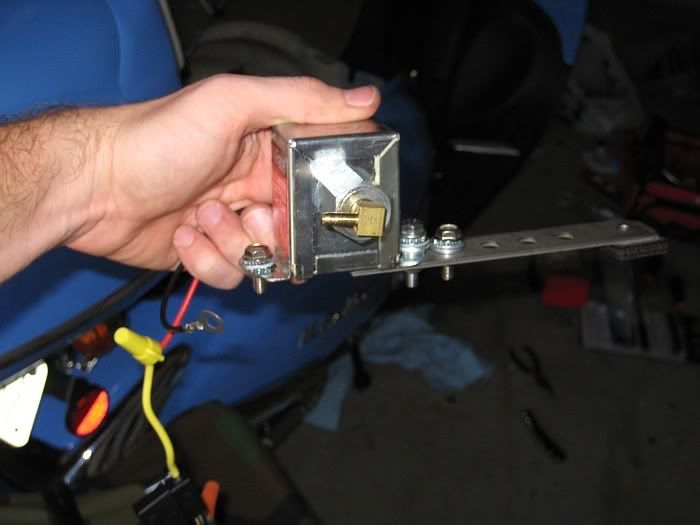

This fuel pump is also 2-3.5 psi. It has a very rigid metal mount and it is larger than the above photo makes it look. It is comparable to the size of a raquetball. Here are a few pics of mine:

The Facet models advertise a few features that the Mr. Gasket brand does not have. Apparently, the Facets have a built-in pressure regulator and also the Facets have a check valve (Mr. Gasket 42s has neither of these apparently).

You can see all of the fuel pumps that Facet-Purolator makes at the following link:

www.facet-purolator.com/index.php?option=com_content&task=category§ionid=7&id=16&Itemid=31

I bought my Facet fuel pump at NAPA. It was NAPA part number 6101052. It came in a small white OEM box that does not say Facet or Purolator anywhere on it.

Ok, so I've got my fuel pump, either the Mr. Gasket 42s or one of the Facet models, so where do I put it?

Well, I got some advice that clouded the issue quite a bit. I was told in both the Facet/Mr. Gasket manuals, and by dawgs here that these pumps could push fuel much better than they could pull it. I recall a thread here where someone stated it is "impossible to pull a fluid." So anyways, based on these warnings I did a quick test to determine my fuel pump's ability to pull a fluid. This fuel pump was about 3 feet above the level of the water. The hoses were not primed in any way. As you can kind of see in the video, it took about .5-1 second for the facet pump to prime and to produce a more than sufficient stream of water.

Based on this successful test, I mounted this Facet fuel pump in the same location that my old hockey puck fuel pump was located. This location was not ideal because it was 14-16 inches above the bottom of the fuel tank. In this location, any fuel pump would be pulling the fuel vice pushing the fuel. I thought I was good to go based on the above test. Also, I installed an in-line adjustable fuel pressure regulator because I did not want the fuel pressure to force the carburetor float valve open, and have it flood my carb. So I set it the fuel pressure regulator to 3psi, that should be more than enough right? Well no, I hooked it all up and hooked the pump directly to the battery. Lots of noise but no priming, no fuel movement at all, how could that be?? I just proved in my test that the fuel pump could prime 30 inches straight up. Well, I did two things to prevent the pump from priming. I limited its ability to push/pull by setting the fuel pressure regulator. Also, I did not try to start the engine, so the fuel pump could not push any fuel into a closed system. If I had hit started the engine when I initially installed this fuel pump, I would have saved many hours of grief later on. Well, live and learn. So since my spot for the fuel pump above the fuel tank did not work, I had to find a spot below the tank. Doing this would allow the fuel pump to push the fuel instead of pulling it.

So I must say, it is really difficult to find a spot below the fuel tank to mount a fuel pump when the fuel tank is already below the floorboards. I stripped off all of the plastics and the skid plate (what a horrible chore!). I did find one spot, very close to the exhaust header but below the fuel tank. I was using one of the bolts that were normally used to hold on the plastic skid plate. I installed the fuel pump at that location, only using one bolt, to securely install the fuel pump at this location, I would have to drill and tap another for another bolt. As you can see in the below photo, the fuel hoses and fuel filter were hanging, they would have to be supported by flex cuffs and the plastic skid plate (once installed again). I didn't like this solution, all it would take is one fuel hose to bump into that exhaust pipe to make for a bad day.

I actually made a short and very incomplete how-to video in which I feature this position for the fuel pump. I could have gotten it to work down there, but it would have been risky in the long run.

I knew I hadn't fully vetted the idea of mounting the pump back up higher (where it was much safer). So before permanently installing the pump down below, I installed back up to that previous spot above both the fuel tank and carb. This time I put the fuel pressure regulator on 4.5 psi and I tried to start the engine while the pump was turned on. Well, doing those two things allowed the fuel pump to very quickly prime and push fuel to the carb. After some tinkering with the air/fuel mixture screw and idle screw, I had the il bello idling very smoothly with the electric fuel pump. Even with the regulator at 4.5psi, it was not flooding my stock 24mm CV carb. All was well.

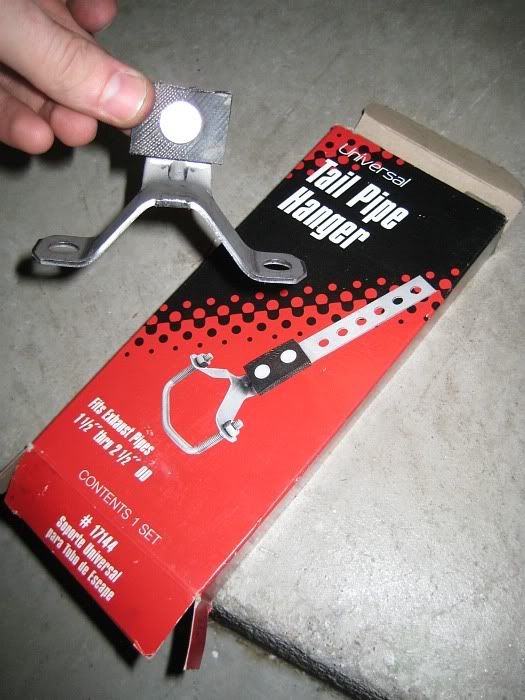

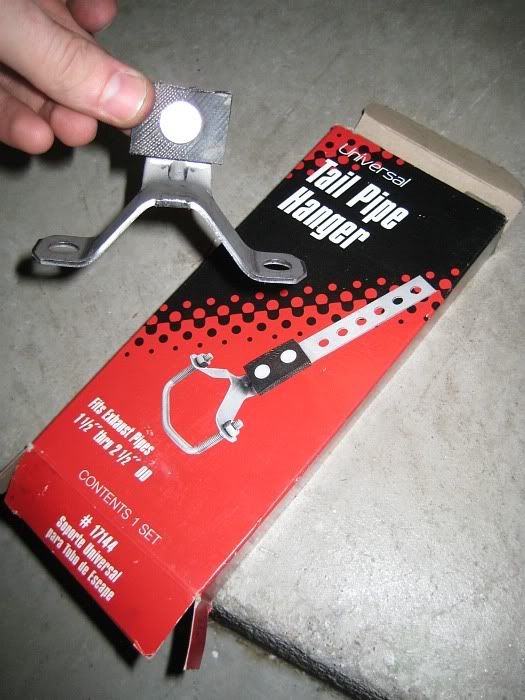

Check out the photos of my fuel pump mount. I used a portion of an exhaust tail-pipe hanger.

Just to make this clear, the hoses are in this order. From the fuel tank -> in-line fuel filter -> electric fuel pump -> adjustable pressure regulator -> carburetor. I know that is obvious to us now, but a few months ago when I first got on scoot dawg, I didn't even know what a carburetor was.

Hooking up the eletricity These electric fuel pumps work on DC not AC current! Your lights on your scooter are powered by AC, so you cannot simply splice one of those wires and hook up your fuel pump to it. You must find a DC wire that is controlled by the ignition. Your endstate is this: turning your key turns on the fuel pump and lights. You must have a multimeter in order to know what wires are AC and DC, and to know which wires are controlled by the ignition. Multimeters are very cheap, I got mine at Harbor Frieght for $2.99. It isn't fancy, it does its job. For those who do not know how a multimeter is to be used, you hold the black lead onto the frame of the scooter, and then you touch the red lead to a source of power. Based on your type of multimeter, it should then tell you whether it is AC or DC and the other key characteristics of the current. So you poke around with your key turned on until you find something that is about 12 volts DC. Turn your key off and see if it still says 12 volts. If it turned off, you found a spot to splice your fuel pump wire into. Under the front plastics of my il bello, I found the perfect spotto connect my fuel pump to. Here's the photos: THESE ARE UNDER THE HANDLE BARS IN THE FRONT OF THE SCOOTER.

That green wire that I am crimping is the new wire going to the fuel pump. There was nothing in that spot before that green plug. It was as if someone planned ahead for me for this install. I refuse to give credit to the Chinese. Anyways, I found that spot, tested it with the multimeter, I crimped it, pulled that plastic down over it, and then wrapped it with electrical tape to keep the elements out. Could not have been easier. I thread the wire around the frame, under the fuel tank and back up to the fuel tank, being very careful not to expose the 16 gauge wire to any heat or friction. Make sure you move your handle bars back and forth a lot to ensure you have plenty of built-in slack in the wire.

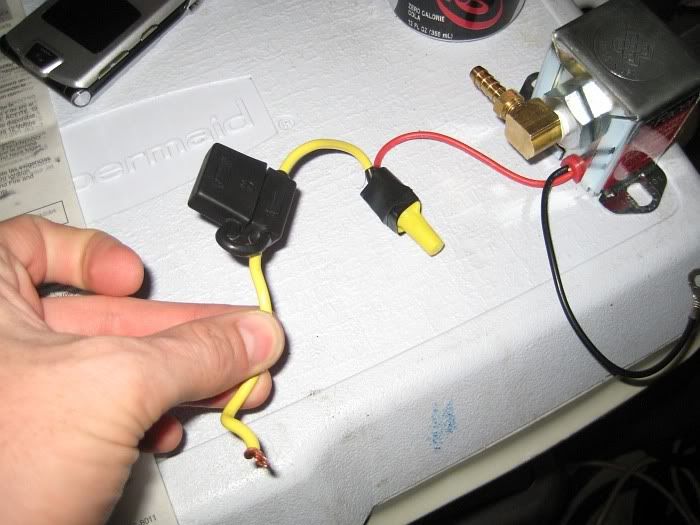

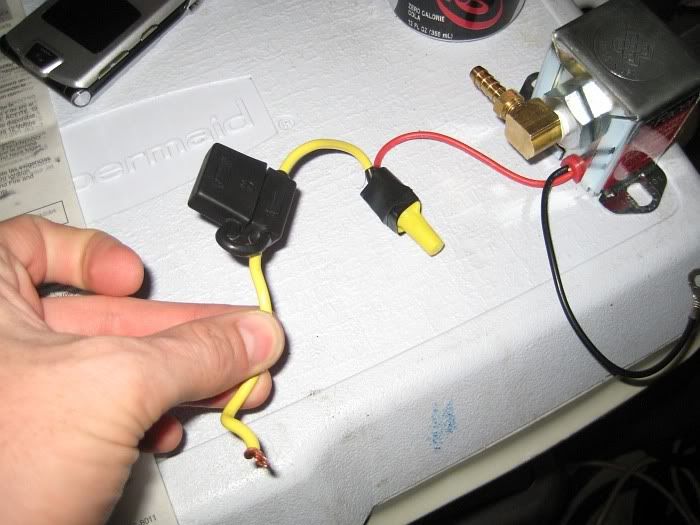

You also must get an in-line fuse holder + fuse. Very easy and it protects your system in case your fuel pump goes bad (or you hook it up backwards). At Autozone I picked up the Bussmann branded fuse holder, it says #12 lead wire, 30 amp max, model name BP/HHG-RP. It came in a yellow package. The fuses were about 10 feet away, but I got the 5 amp blade fuses (which facet recommends). Also made by Bussmann, the model # is BP/ATC-5-RP. Its package is yellow too. Here's a photo of the inline fuse holder.

The negative lead from your fuel pump needs to be affixed to the frame of the scooter somehow. I used the bolts that were holding the fuel pump to the frame, easy enough.

So the positive wire from the fuel pump should connect to -> inline fuse holder (with 5amp fuse in it) -> positive DC wire that is controlled by the ignition. Just look at the photos above. Very simple.

Lessons I've Learned Along the Way

- Work in a ventilated area, I breathed in toxic amounts of fuel doing this project after dumping fuel all over myself many times.

- If your multimeter says your battery is -12 volts, it probably means your black and red leads have been switched

- You have to tighten your 1/8" barbed fuel nipples very very tight to ensure they do not leak. I mean seriously, get two wrenches and pull them in opposite directions until you cramp up. Also, carefully use teflon tape. I had a lot of leaky connections until I did this.

- True Value has A LOT more of the 1/8" thread to 1/4" barb stuff that you'll need. They have the 90 degree angles. Skip Home Depot and Lowes. Also, True Value has a better selection of metric nuts, flared bolts, and washers. The local motorcycle shops were useless, go to True Value or a plumbing place.

- Don't do a fuel pump test with water. Some of that water makes it way into the carb and everything will sound and feel bad when that engine tries to start. Stupid me.

- Use Goodyear 1/4" fuel line when possible. It is very very durable, even better than the Goodyear 3/16" fuel line which is not bad.

- If you've unplugged the spark plug, don't spend too much time wondering why the scooter won't start.

I went on a 60 mile ride today down to La Jolla, CA and back. Up and down some very steep hills at Torrey Pines State Park and everything worked perfectly. I was at WOT most of the time and not one fuel starvation bog. I hope this thread will be helpful to our new members who want to start a project but need a lot of info in one place.

Thanks to the dawgs who helped me complete this (Earlw, therustyaxe, and a few others).

One last photo, this is what your garage will look like when you're in the middle of this project. Have a great weekend!

Have a great weekend!

The problem: At wide-open-throttle there is very little vacuum pressure, therefore a vacuum operated fuel pump frequently cannot produce enough fuel to keep up with engine demand. When riding at WOT for distances greater than 5 or so miles, I sometimes would have a bog from "fuel starvation." It is my understanding most if not all Chinese 150cc scoots come with such a vacuum operated fuel pump. Of course, a fuel pump is only necessary when your fuel tank is below the level of the carburetor. So my carb was not getting enough fuel to keep up with the engine, what are my options?

Two Solutions

Solution #1: Replace the stock vacuum pump that looks like a hockey puck with a higher volume vacuum-operated pump. A very popular replacement is the Mikuni DF-44 vacuum pulse pump. I have read many accounts that using this Mikuni DF-44 fixed the dawg's fuel starvation issues.

This is what my stock vacuum-operated fuel pump looks like.

This is what the Mikuni DF-44 looks like:

The Mikuni DF-44 can be rebuilt too at minimal cost. Here is one reliable dealer who sells this popular DF-44. www.aircraftspruce.com/catalog/eppages/mikunifuelpump1.php

Solution #2: Install an electric fuel pump. By going with an electric fuel pump, you will no longer rely on vacuum hoses in order to suck fuel into the carb. I've read that electric fuel pumps are rated to last much longer than the diaphragms in the vacuum-operated fuel pumps. Also, if you plan on installing a larger carburetor and performance parts on your scooter, you will likely need to send fuel to the engine at faster rates. This is the reason I went with the electric fuel pump as opposed to the Mikuni DF-44.

So which electric fuel pump? Well there are many choices, but there are a couple of frontrunners.

This a link to the Mr. Gasket 42s. However, the one I bought from Autozone was bulkier and made out of black plastic, with a black plastic mount.

www.amazon.com/gp/product/B000BWE4RC?ie=UTF8&redirect=true

It is a 2-3.5 psi electric fuel pump. Many dawgs have installed this electric fuel pump with success. It is available at Autozone, and many online dealers. I chose not to go with the Mr. Gasket 42s because it was slightly larger and more awkward than the Facet fuel pump I went with.

The electric fuel pump that I went with is a Facet cube fuel pump.

This fuel pump is also 2-3.5 psi. It has a very rigid metal mount and it is larger than the above photo makes it look. It is comparable to the size of a raquetball. Here are a few pics of mine:

The Facet models advertise a few features that the Mr. Gasket brand does not have. Apparently, the Facets have a built-in pressure regulator and also the Facets have a check valve (Mr. Gasket 42s has neither of these apparently).

You can see all of the fuel pumps that Facet-Purolator makes at the following link:

www.facet-purolator.com/index.php?option=com_content&task=category§ionid=7&id=16&Itemid=31

I bought my Facet fuel pump at NAPA. It was NAPA part number 6101052. It came in a small white OEM box that does not say Facet or Purolator anywhere on it.

Ok, so I've got my fuel pump, either the Mr. Gasket 42s or one of the Facet models, so where do I put it?

Well, I got some advice that clouded the issue quite a bit. I was told in both the Facet/Mr. Gasket manuals, and by dawgs here that these pumps could push fuel much better than they could pull it. I recall a thread here where someone stated it is "impossible to pull a fluid." So anyways, based on these warnings I did a quick test to determine my fuel pump's ability to pull a fluid. This fuel pump was about 3 feet above the level of the water. The hoses were not primed in any way. As you can kind of see in the video, it took about .5-1 second for the facet pump to prime and to produce a more than sufficient stream of water.

Based on this successful test, I mounted this Facet fuel pump in the same location that my old hockey puck fuel pump was located. This location was not ideal because it was 14-16 inches above the bottom of the fuel tank. In this location, any fuel pump would be pulling the fuel vice pushing the fuel. I thought I was good to go based on the above test. Also, I installed an in-line adjustable fuel pressure regulator because I did not want the fuel pressure to force the carburetor float valve open, and have it flood my carb. So I set it the fuel pressure regulator to 3psi, that should be more than enough right? Well no, I hooked it all up and hooked the pump directly to the battery. Lots of noise but no priming, no fuel movement at all, how could that be?? I just proved in my test that the fuel pump could prime 30 inches straight up. Well, I did two things to prevent the pump from priming. I limited its ability to push/pull by setting the fuel pressure regulator. Also, I did not try to start the engine, so the fuel pump could not push any fuel into a closed system. If I had hit started the engine when I initially installed this fuel pump, I would have saved many hours of grief later on. Well, live and learn. So since my spot for the fuel pump above the fuel tank did not work, I had to find a spot below the tank. Doing this would allow the fuel pump to push the fuel instead of pulling it.

So I must say, it is really difficult to find a spot below the fuel tank to mount a fuel pump when the fuel tank is already below the floorboards. I stripped off all of the plastics and the skid plate (what a horrible chore!). I did find one spot, very close to the exhaust header but below the fuel tank. I was using one of the bolts that were normally used to hold on the plastic skid plate. I installed the fuel pump at that location, only using one bolt, to securely install the fuel pump at this location, I would have to drill and tap another for another bolt. As you can see in the below photo, the fuel hoses and fuel filter were hanging, they would have to be supported by flex cuffs and the plastic skid plate (once installed again). I didn't like this solution, all it would take is one fuel hose to bump into that exhaust pipe to make for a bad day.

I actually made a short and very incomplete how-to video in which I feature this position for the fuel pump. I could have gotten it to work down there, but it would have been risky in the long run.

I knew I hadn't fully vetted the idea of mounting the pump back up higher (where it was much safer). So before permanently installing the pump down below, I installed back up to that previous spot above both the fuel tank and carb. This time I put the fuel pressure regulator on 4.5 psi and I tried to start the engine while the pump was turned on. Well, doing those two things allowed the fuel pump to very quickly prime and push fuel to the carb. After some tinkering with the air/fuel mixture screw and idle screw, I had the il bello idling very smoothly with the electric fuel pump. Even with the regulator at 4.5psi, it was not flooding my stock 24mm CV carb. All was well.

Check out the photos of my fuel pump mount. I used a portion of an exhaust tail-pipe hanger.

Just to make this clear, the hoses are in this order. From the fuel tank -> in-line fuel filter -> electric fuel pump -> adjustable pressure regulator -> carburetor. I know that is obvious to us now, but a few months ago when I first got on scoot dawg, I didn't even know what a carburetor was.

Hooking up the eletricity These electric fuel pumps work on DC not AC current! Your lights on your scooter are powered by AC, so you cannot simply splice one of those wires and hook up your fuel pump to it. You must find a DC wire that is controlled by the ignition. Your endstate is this: turning your key turns on the fuel pump and lights. You must have a multimeter in order to know what wires are AC and DC, and to know which wires are controlled by the ignition. Multimeters are very cheap, I got mine at Harbor Frieght for $2.99. It isn't fancy, it does its job. For those who do not know how a multimeter is to be used, you hold the black lead onto the frame of the scooter, and then you touch the red lead to a source of power. Based on your type of multimeter, it should then tell you whether it is AC or DC and the other key characteristics of the current. So you poke around with your key turned on until you find something that is about 12 volts DC. Turn your key off and see if it still says 12 volts. If it turned off, you found a spot to splice your fuel pump wire into. Under the front plastics of my il bello, I found the perfect spotto connect my fuel pump to. Here's the photos: THESE ARE UNDER THE HANDLE BARS IN THE FRONT OF THE SCOOTER.

That green wire that I am crimping is the new wire going to the fuel pump. There was nothing in that spot before that green plug. It was as if someone planned ahead for me for this install. I refuse to give credit to the Chinese. Anyways, I found that spot, tested it with the multimeter, I crimped it, pulled that plastic down over it, and then wrapped it with electrical tape to keep the elements out. Could not have been easier. I thread the wire around the frame, under the fuel tank and back up to the fuel tank, being very careful not to expose the 16 gauge wire to any heat or friction. Make sure you move your handle bars back and forth a lot to ensure you have plenty of built-in slack in the wire.

You also must get an in-line fuse holder + fuse. Very easy and it protects your system in case your fuel pump goes bad (or you hook it up backwards). At Autozone I picked up the Bussmann branded fuse holder, it says #12 lead wire, 30 amp max, model name BP/HHG-RP. It came in a yellow package. The fuses were about 10 feet away, but I got the 5 amp blade fuses (which facet recommends). Also made by Bussmann, the model # is BP/ATC-5-RP. Its package is yellow too. Here's a photo of the inline fuse holder.

The negative lead from your fuel pump needs to be affixed to the frame of the scooter somehow. I used the bolts that were holding the fuel pump to the frame, easy enough.

So the positive wire from the fuel pump should connect to -> inline fuse holder (with 5amp fuse in it) -> positive DC wire that is controlled by the ignition. Just look at the photos above. Very simple.

Lessons I've Learned Along the Way

- Work in a ventilated area, I breathed in toxic amounts of fuel doing this project after dumping fuel all over myself many times.

- If your multimeter says your battery is -12 volts, it probably means your black and red leads have been switched

- You have to tighten your 1/8" barbed fuel nipples very very tight to ensure they do not leak. I mean seriously, get two wrenches and pull them in opposite directions until you cramp up. Also, carefully use teflon tape. I had a lot of leaky connections until I did this.

- True Value has A LOT more of the 1/8" thread to 1/4" barb stuff that you'll need. They have the 90 degree angles. Skip Home Depot and Lowes. Also, True Value has a better selection of metric nuts, flared bolts, and washers. The local motorcycle shops were useless, go to True Value or a plumbing place.

- Don't do a fuel pump test with water. Some of that water makes it way into the carb and everything will sound and feel bad when that engine tries to start. Stupid me.

- Use Goodyear 1/4" fuel line when possible. It is very very durable, even better than the Goodyear 3/16" fuel line which is not bad.

- If you've unplugged the spark plug, don't spend too much time wondering why the scooter won't start.

I went on a 60 mile ride today down to La Jolla, CA and back. Up and down some very steep hills at Torrey Pines State Park and everything worked perfectly. I was at WOT most of the time and not one fuel starvation bog. I hope this thread will be helpful to our new members who want to start a project but need a lot of info in one place.

Thanks to the dawgs who helped me complete this (Earlw, therustyaxe, and a few others).

One last photo, this is what your garage will look like when you're in the middle of this project.

Have a great weekend!

Have a great weekend!

Roketa MC-60

Roketa MC-60  Tiger Cub

Tiger Cub

Have a bone

Have a bone

) Have another for letting us hijack and take a few posts hostage.

) Have another for letting us hijack and take a few posts hostage. ) .............and were talking about [glow=red,2,300] FIRE? [/glow]........[glow=red,2,300] FIRE? [/glow] I ain't afraid of no [glow=red,2,300] FIRE [/glow]

) .............and were talking about [glow=red,2,300] FIRE? [/glow]........[glow=red,2,300] FIRE? [/glow] I ain't afraid of no [glow=red,2,300] FIRE [/glow]